LINTER S.A. has extensive experience in the development of complex technologies and implementation of production facilities for mechanical coal processing plants as well as systems, machines and equipment applied in these technologies such as:

- dense medium separators,

- gravity jigs,

- settlers,

- dense media preparation and regeneration process lines,

- technologically-advanced filter presses

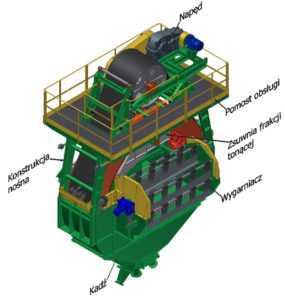

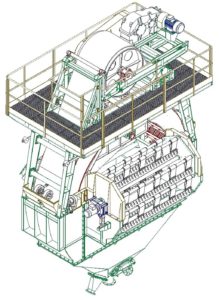

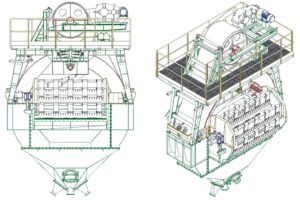

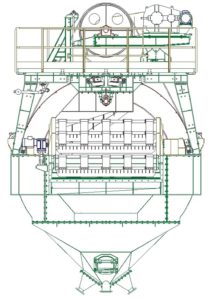

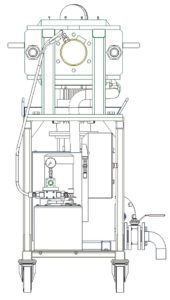

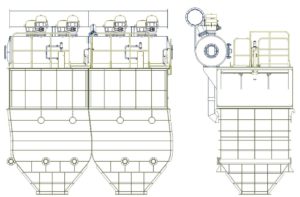

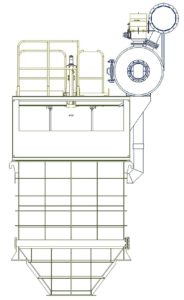

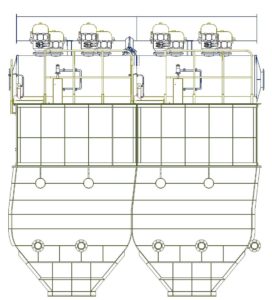

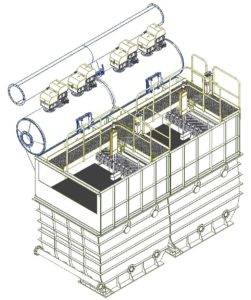

Dense medium separators

DISA-type suspension separators are intended for dense (e.g. magnetite) liquid separation. Their operation is based on the following phenomenon: particles float at a liquid surface if the specific weight of particles is lower than the specific weight of liquid and they sink if their specific weight is higher than its specific weight. Dense medium separators are primarily used at mechanical coal-processing plants.

The principle of a DISA-type suspension separator and its operation is that input material (feed) intended for dense liquid separation is split – within a flume – into floating and sinking fractions. Floating fractions move together with dense liquid towards an overflow where – by means of a picker – they are discharged outside the separator. And sinking fractions – after going down to transferring wheel compartments – are raised to a certain height. When material gathered in transferring wheel compartments exceeds the natural angle of sliding, it goes down to a chute which discharges sinking fractions outside the separator.

There are double-product or triple-product DISA-type suspension separators produced and intended for the grain size class of 200 – 20(16) mm.

|

|

|

|

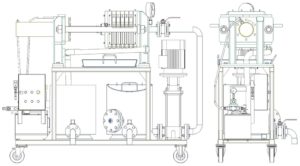

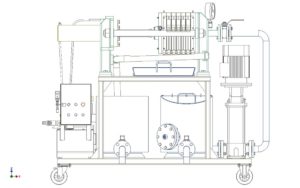

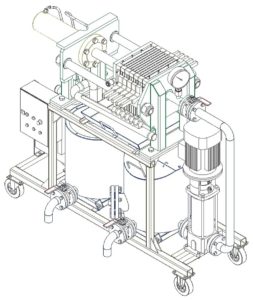

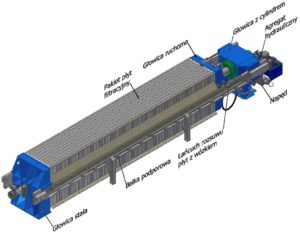

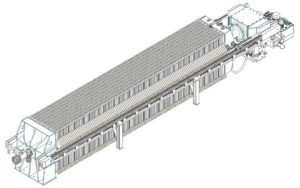

Filter presses

A filter press is a specific machine designed for mechanical separation (drainage) of solids from within all kinds of suspensions.

Our chamber filter presses are used to drain technological sludge and water waste in various fields of industry:

- in the chemical industry – in technological processes,

- in metallurgy – for drainage of ores and concentrates,

- in the heating industry – for desulphurisation of exhaust gases,

- in the mining industry – for drainage of post-flotation sludge and waste,

- at municipal and industrial (post-galvanic) wastewater treatment plants etc.,

- in other technological processes which require drainage.

A standard filter press is composed of:

- a press bearing construction with a hydraulic cylinder,

- a polypropylene filter package with a set of filter fabrics,

- hydraulic power unit,

- press power supply and control system

A operational cycle of a given press starts with squeezing filter plates (closure). Afterwards it is ready for sludge to be pressed into fixed chambers onto partition-forming filter fabrics; filtrate (effluent) is discharged from the press centrally via a collection manifold or individually from all plates. After filling in spaces between plates (chambers) with sludge (called a filter cake) and removing sludge remnants from the feed manifold with compressed air, filter plates get open. In the course of getting plates open and the main piston of its hydraulic cylinder moving back, the movable head (coupled to it) comes back to its starting position.

When the movable head sets its movement, filter plates get open (by means of special carriages) and empty (e.g. filter cakes falling from the chambers onto a collection conveyor belt or a collecting container). When the press is fully discharged, its operational cycle is finished and it is ready to start a new cycle.

As requested by the Client, presses may be further equipped with:

- sludge pumping system,

- power-driven tilted flaps,

- collection of sludge – with the use of a stationary or self-propelled container, conveyor belt,

- filer fabric washing system,

- microprocessor control system.

|

|

|

|

|

|

|

|

|

|

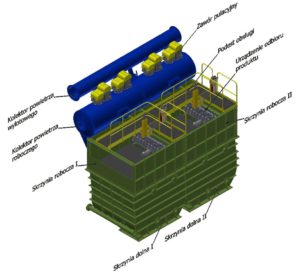

Jigs

Jigs are designed for dense liquid separation of coal or other minerals to be used in processing plants. Dense liquid separation in a jig is based on that input material (e.g. coal) is separated into fractions by gravity in pulsating water (medium) according to its density:

- light – i.e. separated coal concentrate,

- heavy – i.e. waste or possibly intermediate product

The following types of jigs are manufactured in terms of the grain size class of separated coal.

- Small-grain jigs – designed to separate fine coal with its granulation at 30/20÷0,5 mm at processing plants

- Medium-grain jigs – designed to separate fine coal with its granulation at 70/50÷0,5 mm at processing plants

- Large-grain jigs – designed to separate fine coal with its granulation at 120/-20÷10 mm at processing plants

|

|

|

|

|

|

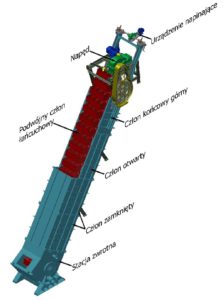

Bucket elevators

Bucket elevators are designed for vertical transport of bulk and granular materials and are used in various industries:

- in mechanical coal processing plants – they transport and drain products from/off jigs,

- in heat and power plants – they transport coal within carburisation installations,

- for transportation of all kinds of particles, bulk materials and biomass,

The standard sizes of manufactured bucket elevators used for drainage are as follows:

- B-630mm

- B-800mm

- B-1000mm

Bucket elevators manufactured in our factory have many applications and are characterised by durability and reliability.