LINTER S.A. owns two production plants – the main one in Łobzów near Wolbrom and the other one in Wodzisław Śląski.

The main production plant manufactures all types of conveyor parts and components as well as other specialised machines and steel structures.

Currently we produce and provide services for such industries and sectors as, among others: mining, cement industry, drilling sector, energy generation, construction, railways.

Apart from the production of our machines (among others: conveyors, suspension separators, filter presses) we also run the production of:

supporting structures, conveyor routes

platforms, railings, supports

elements of exhaust-gas discharge and desulphurisation systems

silos, tanks

and many other elements

Our versatile machine park let us implement numerous projects in the metal industry and render cooperation services:

Milling, boring, drilling and tapping operations

We are equipped with a numerically controlled TOSS VARNSDORF horizontal milling-drilling central unit, with a total workspace of 11000 x 2000 x 2500 mm (9.5 m is the maximal length of an individually treated workpiece). The machine is equipped with two headstocks positioned opposite each other. Each column – with a spindle diameter of 130 mm – is capable to operate independently all over the way and synchronously within 4000 mm at the maximal working feed of 8000 mm/min and working spindle rotation of 3000 min. Additional facilities include:

- two turntables (1.4×1.6 and 2.0×2.5)

- angle heads, including automatically-positioned and double-axis indexed ones steered by the boring control system

- gantry milling machines in the range up to 5400 x 1800 x 750 mm

- lifting capacity of cranes up to 12.5 t

- vertical and horizontal conventional milling machines.

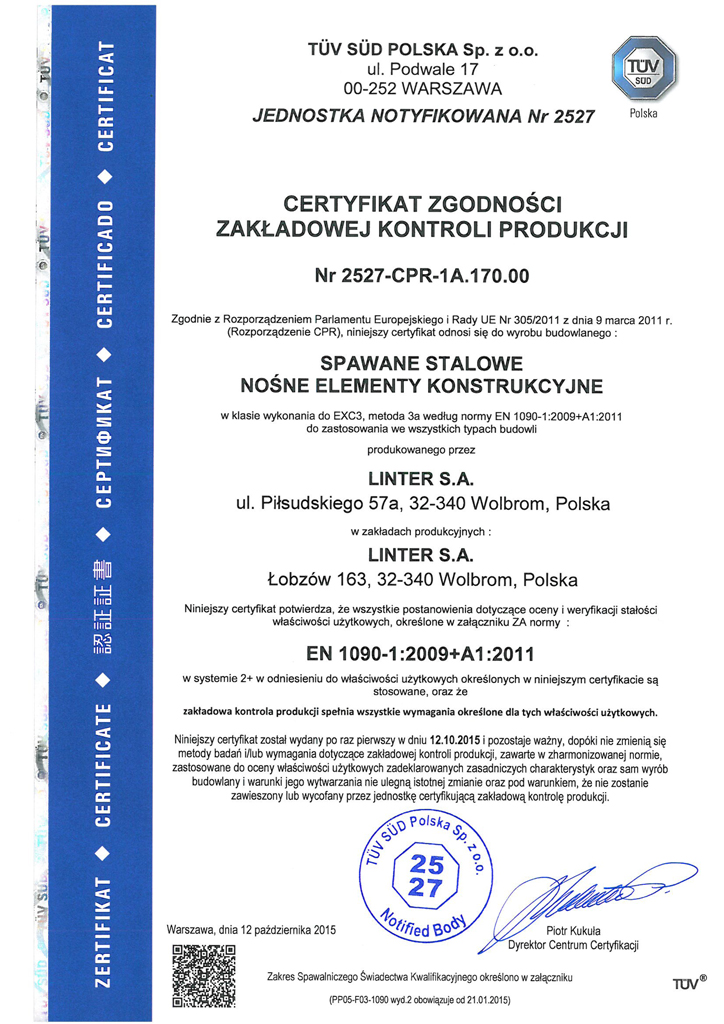

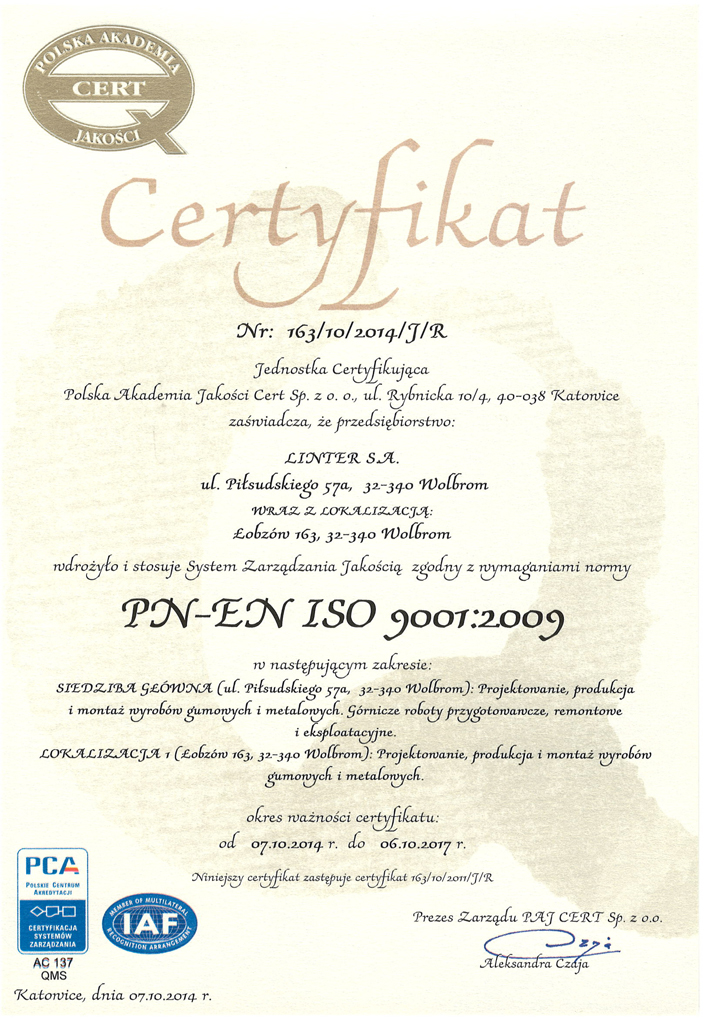

Welding operations

- MIG, MAG, MMA welding

Ironwork operations

Cutting and burning-out operations

- cutting: bars, tubes, profiles up to Ø 450 mm

- burning-out: metal sheets (numerically controlled burners) up to 2000 x 6000 mm

Surface-cleaning through blasting and sandblasting

Spray and powder painting

Turning operations

- external lathing up to Ø 1200 mm and L=4000 mm, part weight up to 3 tons

- lathing at CNC lathers up to Ø 500 mm

Chiselling up to Ø500 x 200 mm

Rubber coating Ø1900 x 6000 mm

A selection of our projects in the range of steel constructions farbrication

- Steel construction of building grids and beams for roof installation – “Dominikański” Building in Wrocław

- Construction of building braces for MPL Airport in Pyrzowice with a total roof area of 9000 m2

- Construction of bar-tacking for TRIMO panels, fire-protected, for Philip Morris in Kraków, with a total roof area of 10000 m2

SKANSKA S.A. EXBUD KIELCE

- steel constructions for hypermarkets – SELGROSS

WROMOSTAL Wrocław

- elements of cooling towers

UNISERV- PIEC BUD S.A.

- steel constructions -outside shutters with anti corrosive protection

- steel construction for cooling chamber and inlet funnel of exhaust gas cooling chamber

KGHM Zanam Legmet S.A.

A selection of our cooperation services in the range of mechanical treatment

- mechanical treatment of rails

TRACK TEC S.A.

- mechanical treatment of machine bodies and parts

ALCHEMIA S.A.

- mechanical treatment of cooling towers

Uniserv – Piecbud S.A.

- mechanical tratment of machine bodies and parts

KS Konstrukcje Stalowe KTR Group Sp. z o.o.