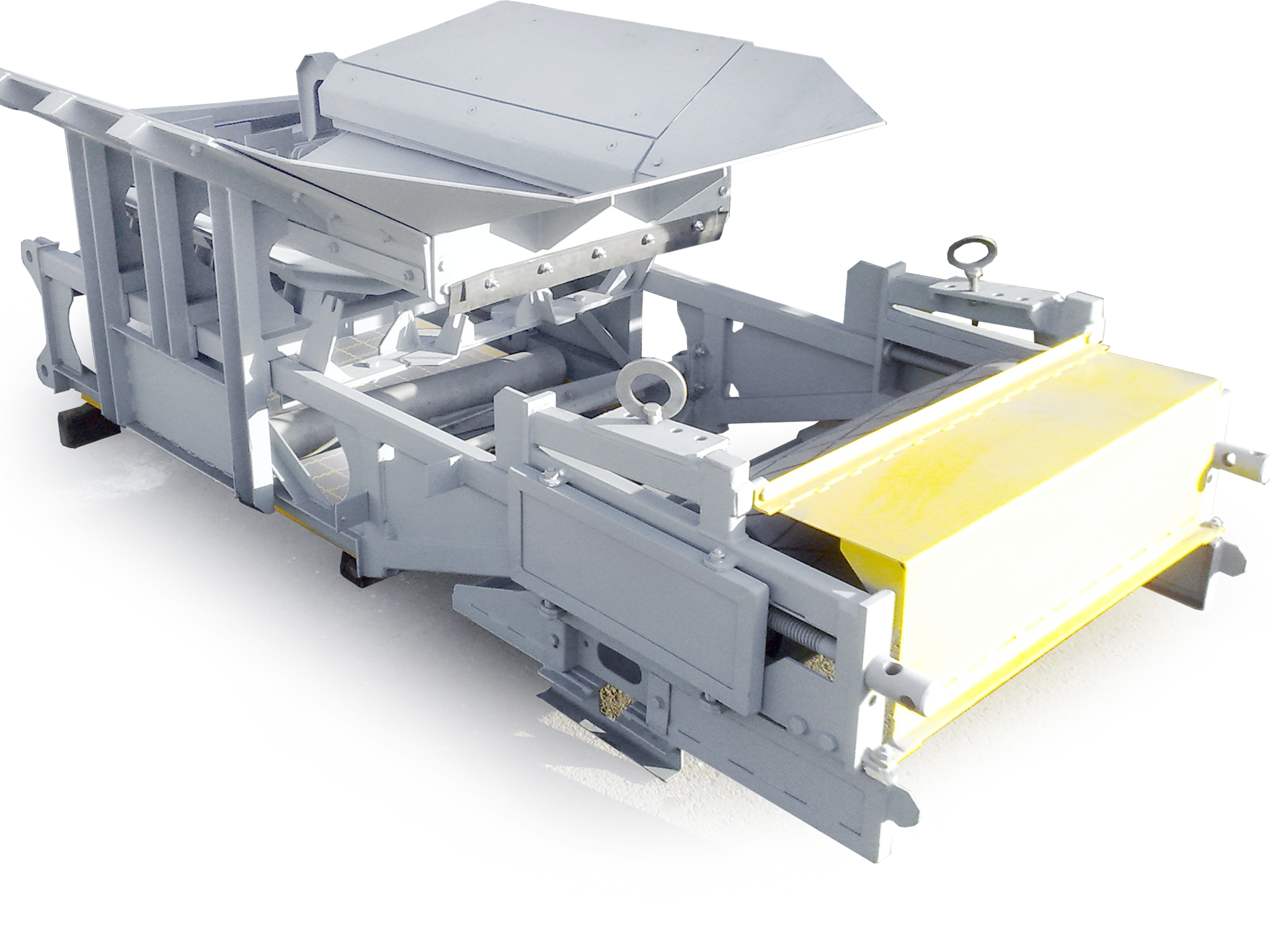

The assortment offered by the Linter Group is complemented by the production of key conveyor components. Our components are used by many producers of technological process and lines at home and abroad.

We offer:

- driving stations

- charging units for easy material loading

- belt tension and storage stations

- supporting structures for conveyors

- driving, directional and return drums

- idlers

We offer standard components made available in line with our catalogue offer as well as specifically designed according to customer’s requirements.

Such elements as idlers, drums are manufactured by MET-ROLL Sp. z o.o, part of our Group.

IDLERS

The product assortment offered by MET-ROLL sp. z o.o. includes the production of the following types of idlers: smooth / disc-based / ring-based / supporting / directional / garland-typed.

A large part of our production is made by non-standard products tailored to customer’s requirements. The key recipients of our idlers include: coal mines, mineral mines, cement plants, power stations, heat-power stations and other customers engaging continuous transport units – both at home and abroad.

Our idlers have been approved by the Central Office of Mining (pol. Główny Urząd Górniczy, GIG) to be used in underground mines.

SPECIFICATION OF IDLERS

- Types: plain / disc / ring / support / directional / garland

- Idler diameter (mm): 51 / 54 / 63,5 / 108 / 133 / 159 / 194 / 215 / 254 (may vary depending on a given order)

- Maximal length: up to 2500

- Bearing hub: cast iron / steel (depending on its intended use)

- Sealing: plastic / steel (depending on its intended use and size)

- Coat thickness: depending on an idler and its length

- Maximal length of idler axis (mm): 2600

- Diameter of axis idler (mm): 20 / 25 / 30 / 35 / 40 (may vary depending on a given order)

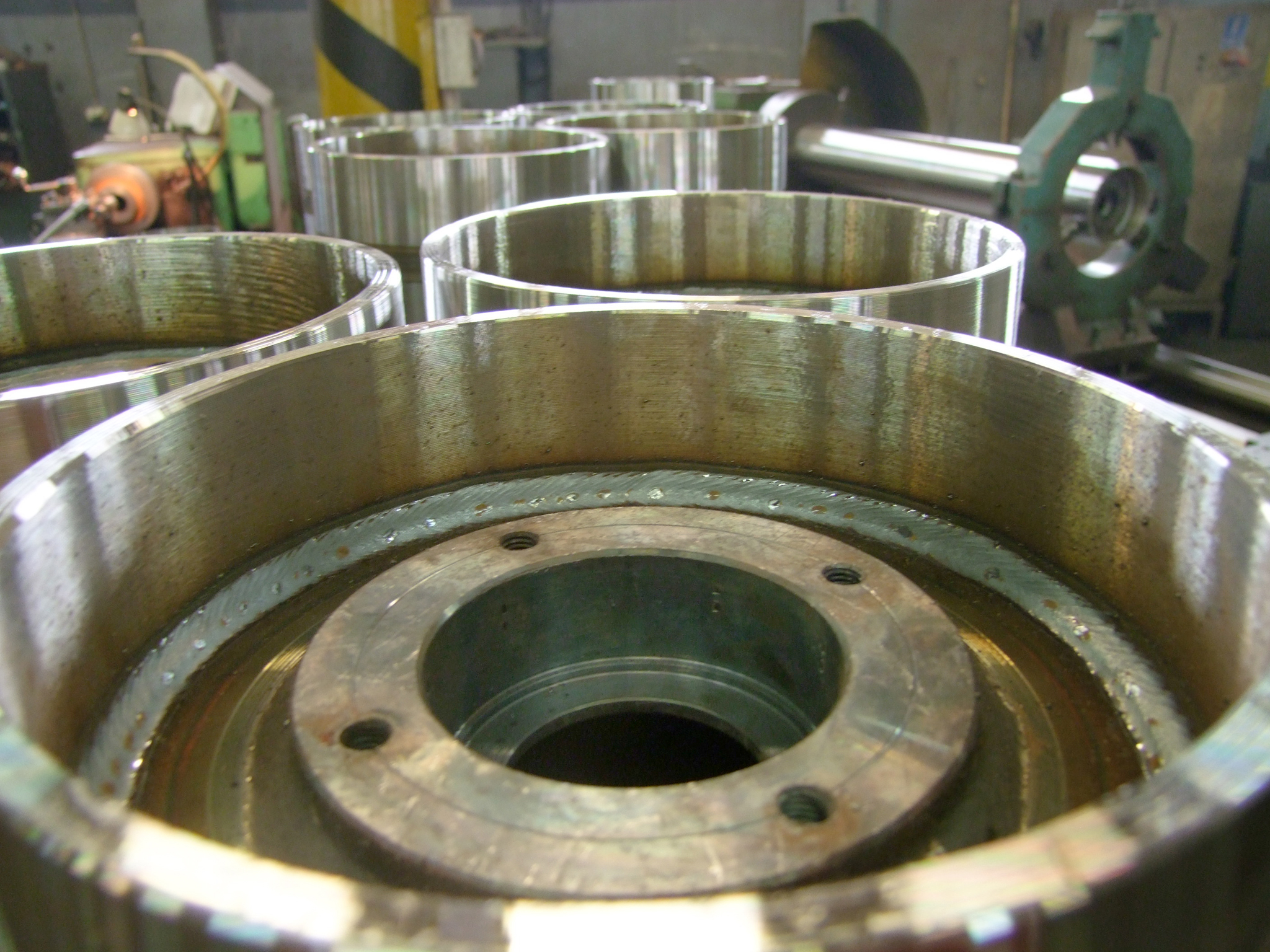

DRUMS

Our conveyor drums are renowned for their quality of workmanship and exceptional durability.

EXEMPLARY SPECIFICATION OF CONVEYOR DRUM

- Types: driving / reversing / tensioning

- Maximal width (mm): up to 2000 (may vary depending on a given order)

- Maximal diameter (mm): up to 1800

- Type of drum casing: steel / plain or treaded rubber / ceramic (its thickness may vary depending on a given order)

- Shape of drum casing: flat / convex

SHAFTS

Linter produces high-quality steel shafts for various kinds of drums with their length up to 3000 mm. A shaft diameter depends on its overall weight – shafts to 3.5 Mg (t) are dealt with at the production plant in Łobzów. Shaft can be combined with bearings by welding or DOBIKON ring – depending on customer’s preference and intended use.

Shaft diameters are calculated and adjusted by LINTER engineers so as to perfectly fit drums ordered by customers.

EXEMPLARY SPECIFICATION OF DRUM SHAFT

- Maximal length (mm): up to 3000

- Maximal diameter (mm): depending on its weight (up to 3.5 Mg [t])

- Bearing mounting: welded / DOBIKON ring

ŁOŻYSKA I PIASTY

Łożyska LNT używane w produktach firmy Linter to marka należąca do Linter Group. Są wykonywane według autorskiego projektu, zgodnie z restrykcyjnymi wymogami jakości. W zależności od przeznaczenia bębna i woli klienta, producent montuje w bębnie łożyska kulkowe lub baryłkowe, które mogą zostać zamontowane wewnątrz lub na zewnątrz wału (na końcu wału bębna).

PRZYKŁADOWA SPECYFIKACJA ŁOŻYSKA

- Typ łożyska: kulkowe / baryłkowe

- Montaż łożyska: wewnętrzny / zewnętrzny

- Producent: LNT – własna marka Linter Group

- Maks. średnica piasty łożyska (mm): 1000